Along with the other tools that I recently bought in an auction lot were these two items that I'd never run across before - never knew such a thing existed. They're two "jobsite" saw vises, made to be compact enough to carry in a toolkit. I'm certain they're intended to attach to a saw horse for jobsite sharpening of saws.

The first is by E. C. Stearns. It's got a screw clamp to attach it to a piece of wood for stability and the clamp swivels out of the way for compact stowage. The vise clamps a saw in its jaws using a cam mechanism.

|

| E. C. Stearns no. 500 saw vise |

|

| Stamped name shows up great after some cleanup |

|

| No. 500 |

|

| Underside shows the swiveling arm with clamping screw |

|

| End view of the vise shows the clamping screw in clamping position |

|

| Here it is clamped onto a 2x4 that is held in my bench vise |

|

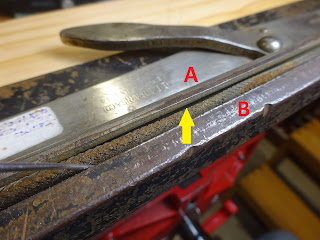

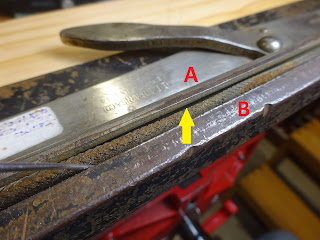

Top view. I'm holding the cam lever. Yellow arrows show slots allowing part A to slide

when cam lever is moved to right to squeeze against part B.

Green arrow shows the gap between parts A and B when cam lever is to left. |

|

| When lever is moved to right, A is pressed against B and the gap is gone |

|

| Here it is clamping a 12" gents saw |

|

| And a closer shot |

|

And it works pretty well! Shown here is an inverted "L" shaped wood piece that the vise

is clamped to; the "L" block clamps in my end vise to raise the work up to better level. |

One last thing about this saw vise. Part A has a hollow area up where it clamps to part B. And in that hollow is a length of braided steel wire whose diameter (approx. 1/4") is slightly greater than the depth of the hollow. My guess is that the braided wire has some compressibility and gives a better hold on the whole length of the saw plate.

|

| Dental tool (left) is lifting the braided wire out from where yellow arrow points |

|

| This shows how the wire is attached: it's simply stuffed through a hole in each end! |

And here's the only problem. The wire is not taut enough to stay in place in its groove. I have to be very careful that it's in the groove when clamping a saw plate - otherwise I clamp a big bend in a saw plate. When researching this, I read that someone replaced the wire with some rubber screening spline (or something similar). That's an option, but I'm not sure if I want to replace an original part.

This is getting long, so I'll write about the second saw vise in another post. Until then ...

No comments:

Post a Comment