A few weeks ago I made a post and rung stool from fresh-cut wood. The following picture was taken about that time when I was just experimenting with some cord weaving.

|

| The post and rung stool with an initial experiment in weaving |

That was about a month ago. I started on the seat again, but I'd been hung up on what to do. The two types of weaving I considered are like in these two photos from the internet.

|

| Internet picture |

|

| Pic form Caleb James' site |

Danish cord is expensive stuff and I didn't want to be wasteful. The pattern on the left uses less cord, but typically uses nails. The pattern on the right uses more cord and a few tacks.

Most of the cord seats I've seen with the first pattern use L-shaped nails on the insides of the rails to turn the direction of the cord. This avoids the waste associated with cord going fully front-to-back or side-to-side under the seat.

|

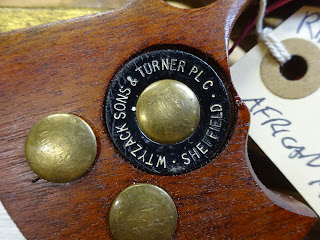

| Showing use of the L-shaped nails used on the stool I made in early 2022 |

The second pattern is more common using other materials like rush or other material thicker than Danish cord, and it uses only a few tacks.

There are two reasons I didn't want to use nails on this post and rung stool. First, I just like to avoid using nails if I can. And second, my rungs are only 7/8" octagonal and there really isn't enough room to use them.

After thinking about it for far too long, I went with the first pattern, but modified for not using nails.

The initial experimenting did allow me to work out some spacing issues. For the front-to-back cord, I found that it would look good with 5 or 6 loops around the rung between each full front-to-back cord.

|

Front left leg of stool is at shown in this photo.

Two extra wraps (four total) at furthest left front-to-back wrap, then 6 wraps around the rung,

then two full wraps and another 5 or 6 wraps around the rung. |

|

Continued this pattern across the seat (ignore the left-to-right pattern for now)

|

There are two issues with this. Notice where the rung joins the post that it necks down from 7/8" to 5/8". Two pics above here you can see a naked rung as well as a wrapped rung that show this. It causes The first couple of wraps to follow that necked-down shape and I don't want the succeeding wraps to slip over the first two.

The second issue with this is that under the chair, after I've completed two front-to-back wraps and 6 wraps around the front rung, I have to angle the cord to begin the 6 wraps around the rear rung before continuing with the next two full front-to-back wraps. It's not an issue for looks because it's on the underside, but when I go to weave the left-to-right cord it's unclear how this will affect things as I get further to the back.

|

| Underside shown: pencil pointing to the angled cord |

In the end, I just went for it and figured out these issues on the fly. First, to avoid the necking down problem, I added a couple extra loops of cord around the rungs and tacked them in place. This helped level the ends.

|

| View from above showing how it fills in the tenon area |

|

| View from inside showing how it was wrapped and tacked |

I don't know if the terms "warp" and "weft" apply to all kinds of weaving, but I get a kick out of using them, so here goes. To make the wrapping easier for the warp (front to back wraps), I made something to help control the cord. I saw something like this on Caleb James' and others' websites.

|

Made from 1/8" thick plywood:

note the two holes under the left coils with cord going through to help keep it from unraveling |

|

| I hadn't planned this, but the size was right to sit it on lower rails - very convenient! |

So I started wrapping. I saw a video where they put four full warp wraps at far left and at far right, but two everywhere else. So that's what I did. But when I got to the right side I found I didn't have an odd number of front-to-back groups of cord.

|

Here I'm counting - 12 groups

Note that I considered putting the weft through just two of the four in the right-most

group of warp cord (essentially making it 13 groups), but later decided against that. |

|

Here I've started the first few rows of weft after fixing the warp. For the fix,

I unwrapped several warp rows and adjusted the number of rung wraps to get 13 warp groups. |

The warp ended up not perfectly symmetric, as there is a lone group of four at the far left and all other groups are of two. In hind sight, it would have been fine with just two everywhere.

|

| Getting close to complete. The last few rows of weft are tougher to weave. |

Weaving the rest of the weft went fine. Note that I'm weaving on the underside of the seat also. Because of the angled cord that I mentioned earlier, I tried to do something to ease the transition. At the beginning and the end of weaving the weft, I went over and under every pair of warp cords. Near the middle, I went over and under two pairs, then three pairs, then back to two pairs so that the angled cords had somewhere to go.

|

| The underside - see the angled warp cords? |

You can also see in the above picture where I tied off the beginning and end of the weft. These are simply tied to a pair of warp cords.

Here's two pictures of the completed seat from above, the second taken after adjusting the spacing of the warp cords. It didn't make a huge difference, but I'm happier that I took the few minutes.

|

| Before adjusting |

|

| After adjusting the spacing |

And the final product.

|

| Ta da ... |

This was a fun project. Just a few months ago, the wood was a living tree. When it fell in a storm, I took a couple logs and made the posts and rungs. Weaving the seat was the icing on the cake.

I probably mentioned this when I posted about a Danish cord stool in early 2022, but weaving this cord is tough on the hands. Near the end, I used an old pair of bicycle gloves and that helped.

Last note: After completing the warp, the seat doesn't feel like it's tight enough. But when the weft goes in, it really tightens it up and becomes quite firm.